Touch hole on flintlock muzzleloader – The touch hole, an indispensable element of flintlock muzzleloaders, played a pivotal role in the ignition process and the evolution of firearms. This comprehensive exploration delves into the historical significance, design, function, maintenance, and safety considerations surrounding this crucial component, shedding light on its profound impact on warfare and hunting.

Definition of Touch Hole

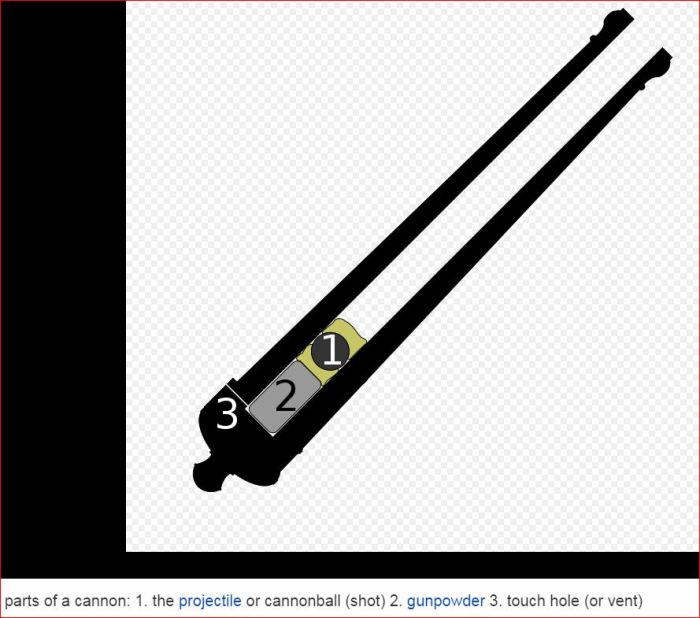

A touch hole on a flintlock muzzleloader is a small hole drilled into the barrel of the gun, just behind the muzzle. It is through this hole that a spark from the flint is directed into the gunpowder pan, igniting the powder and propelling the ball out of the barrel.

The touch hole is a critical part of the flintlock mechanism, and its location and size are important factors in the performance of the gun. The touch hole must be large enough to allow a spark from the flint to reach the gunpowder pan, but not so large that it allows too much powder to escape and weaken the charge.

Location of the Touch Hole

The touch hole is typically located on the top of the barrel, just behind the muzzle. This location allows the spark from the flint to travel directly into the gunpowder pan, without having to travel around the side of the barrel.

The touch hole is also often angled slightly downward, so that any sparks that miss the gunpowder pan will fall harmlessly to the ground.

Significance of the Touch Hole

The touch hole is a small but important part of the flintlock muzzleloader. It is through this hole that the spark from the flint reaches the gunpowder pan, igniting the powder and propelling the ball out of the barrel. The location and size of the touch hole are important factors in the performance of the gun, and a properly sized and located touch hole is essential for accurate and reliable shooting.

Historical Context

The touch hole, a crucial component of flintlock muzzleloaders, has played a significant role in warfare and hunting throughout history.

The development of the touch hole can be traced back to the early 16th century, when firearms emerged as a powerful force on the battlefield. Prior to this, matchlock muskets required a burning match to ignite the gunpowder, a cumbersome and often unreliable process.

The touch hole provided a more efficient and reliable method of igniting the charge, allowing for faster firing rates and increased accuracy.

Role in Warfare

In warfare, the touch hole played a pivotal role in the evolution of firearms. The ability to ignite the charge quickly and reliably gave flintlock muskets a significant advantage over matchlock muskets. During the American Revolutionary War, for example, the Continental Army’s use of flintlock muskets with touch holes proved to be a decisive factor in several key battles.

Role in Hunting

Beyond warfare, the touch hole also played a crucial role in hunting. Flintlock muzzleloaders with touch holes allowed hunters to pursue game with greater precision and efficiency. The ability to ignite the charge quickly and reliably ensured that hunters could take down their quarry with a single shot, reducing the risk of injury or escape.

Design and Function

Touch holes, crucial components of flintlock muzzleloaders, are meticulously designed and constructed to facilitate the ignition of gunpowder, initiating the firing process.

A typical touch hole comprises a small, precisely drilled channel connecting the exterior of the firearm to the interior of the barrel. The channel, often ranging from 0.063 to 0.125 inches in diameter, is carefully positioned to align with the main charge of gunpowder within the barrel.

Construction

- The touch hole is typically formed by drilling a hole through the barrel wall at a specific angle, ensuring optimal communication between the exterior and interior.

- The hole is then meticulously reamed to achieve the desired diameter and shape, ensuring a smooth and consistent channel for the ignition process.

- In some cases, a small vent liner, usually made of brass or copper, may be inserted into the touch hole to enhance durability and prevent fouling or corrosion.

Ignition Process

The touch hole plays a pivotal role in initiating the ignition process within the flintlock muzzleloader.

- When the trigger is pulled, the flint strikes the frizzen, generating sparks that ignite the priming powder in the priming pan.

- The burning priming powder then enters the touch hole, traveling through the channel into the main charge of gunpowder within the barrel.

- The intense heat and flame from the priming powder ignite the main charge, causing a rapid and controlled combustion that propels the projectile out of the barrel.

Maintenance and Cleaning

Maintaining and cleaning touch holes are crucial for ensuring proper ignition and preventing misfires in flintlock muzzleloaders. Regular cleaning removes fouling, debris, and moisture that can obstruct the touch hole, hindering the passage of sparks and compromising the firearm’s performance.

Cleaning Procedures

- Inspect Regularly:Before each use, visually inspect the touch hole for any signs of fouling or obstruction.

- Use a Cleaning Needle:Insert a thin, flexible cleaning needle into the touch hole to dislodge any debris or fouling. Gently rotate and withdraw the needle to clear the passageway.

- Clean with Solvent:Apply a few drops of a cleaning solvent, such as isopropyl alcohol or acetone, into the touch hole. Let it sit for a few minutes to dissolve any remaining fouling.

- Flush with Water:Use a syringe or dropper to flush the touch hole with clean water to remove the dissolved fouling and solvent residue.

- Dry Thoroughly:Use a cotton swab or compressed air to thoroughly dry the touch hole, ensuring it is completely moisture-free before use.

Safety Considerations

Touch holes, crucial for igniting the gunpowder in flintlock muzzleloaders, demand careful handling and adherence to safety protocols to prevent accidents and ensure responsible use.

When handling and using flintlock muzzleloaders, several safety hazards should be considered:

- Unintentional Ignition:Touch holes, if not properly maintained or obstructed, can lead to unintended ignition of the gunpowder charge, causing serious injury or damage.

- Powder Residue:Firing a flintlock muzzleloader leaves behind powder residue in the touch hole, which can accumulate over time. This residue can become a fire hazard if not cleaned regularly.

- Sparks:The act of striking the flint against the frizzen produces sparks that can ignite loose gunpowder or other flammable materials in the vicinity.

Safe Handling and Use, Touch hole on flintlock muzzleloader

To ensure safe handling and use of flintlock muzzleloaders, it is imperative to follow these guidelines:

- Keep the Touch Hole Clear:Regularly inspect and clean the touch hole to remove any obstructions or powder residue. A clogged touch hole can prevent proper ignition or cause a hang fire.

- Handle with Care:Always treat the flintlock muzzleloader as a loaded weapon and handle it with the utmost care. Never point the muzzle at anyone or anything you do not intend to shoot.

- Use Proper Loading Techniques:Load the muzzleloader carefully, ensuring the powder and ball are seated correctly. Avoid overpacking the powder or ball, as this can increase the risk of a hang fire or explosion.

- Control Sparks:Keep the muzzleloader pointed in a safe direction when striking the flint. Avoid sparks coming into contact with flammable materials or loose gunpowder.

- Unload and Clean After Use:After firing, always unload the muzzleloader and thoroughly clean it to remove any remaining powder residue. This helps prevent corrosion and ensures the weapon is ready for safe use next time.

Variations and Adaptations

Touch holes have been adapted for various purposes and designs over time, leading to different types in flintlock muzzleloaders. These variations in touch hole design primarily serve to enhance the ignition efficiency and overall functionality of the weapon.

Different Types of Touch Holes

- Primed Touch Hole:A primed touch hole involves the use of a priming powder or a small amount of gunpowder directly in the touch hole. This priming powder ignites first, creating a flame that then ignites the main charge in the firearm.

- Covered Touch Hole:Some flintlock muzzleloaders feature a covered touch hole. This cover protects the touch hole from moisture, dirt, and debris, ensuring reliable ignition even in adverse conditions.

- Angled Touch Hole:In certain designs, the touch hole is angled to direct the flame more effectively towards the main charge. This angled design improves ignition efficiency, especially in long-barreled firearms.

- Multiple Touch Holes:Some muzzleloaders employ multiple touch holes, allowing for simultaneous ignition of the main charge from different points. This design provides redundancy and enhances the chances of successful ignition.

Query Resolution: Touch Hole On Flintlock Muzzleloader

What is the primary purpose of a touch hole on a flintlock muzzleloader?

The touch hole serves as a channel for the ignition source, typically a spark from flint striking steel, to reach the gunpowder within the firearm’s barrel, initiating the combustion process.

How should a touch hole be properly cleaned and maintained?

Regular cleaning of the touch hole is crucial to prevent fouling and ensure proper ignition. Using a fine wire or a dedicated touch hole pick, gently remove any powder residue or debris that may accumulate.